The Honeywell XNX Universal Transmitter is a versatile gas detection solution, supporting millivolt, electrochemical, and infrared sensors. It offers explosion-proof certification, global compliance, and flexible mounting options for hazardous environments, ensuring reliable and safe operation across industries like oil, chemical, and industrial sectors. Its modular design supports a wide range of sensors, making it a cost-effective and efficient choice for gas detection systems worldwide.

Overview of the XNX Transmitter and Its Importance

The Honeywell XNX Universal Transmitter is a vital gas detection solution, ensuring safety and efficiency in hazardous environments. It supports various sensor types, offering versatility for industrial applications. Explosion-proof and globally certified, it meets strict regulatory standards in high-risk sectors like oil and chemicals. Providing accurate gas monitoring, it prevents accidents and ensures operational safety. Its modular design and universal compatibility enhance flexibility, reducing costs. This makes it an indispensable asset for industries requiring reliable gas detection systems worldwide.

System Requirements and Compatibility

The XNX Universal Transmitter supports millivolt, electrochemical, and infrared sensors, ensuring compatibility with various gas detection needs. It offers flexible mounting options and compatibility with both metric and NPT versions, making it suitable for diverse industrial environments.

Hardware and Software Requirements for Installation

The XNX Universal Transmitter requires specific hardware and software for installation. It supports millivolt, electrochemical, and infrared sensors, with the IR version needing a separate sensor purchase. Hardware includes five threaded ports in metric or NPT versions, offering installation flexibility. Software-wise, it requires the Honeywell Analytics HART DTM Library for configuration and operation. The transmitter is designed for global use in hazardous areas, ensuring compatibility with various industrial standards. Its modular design allows for easy integration of inputs and outputs, optimizing system performance. Proper installation requires adherence to the manual’s guidelines to ensure safety and functionality.

Compatibility with Various Sensor Types

The XNX Universal Transmitter is compatible with a wide range of sensor types, including Sensepoint Optima Plus, Searchline Excel, and model 705 HT sensors. It also supports electrochemical and infrared sensors, offering flexibility for different gas detection needs. For optimal performance, sensors like the IR version may require additional purchases. The transmitter’s modular design allows seamless integration with various sensor technologies, ensuring compatibility across multiple applications. Refer to individual sensor manuals for specific installation requirements. This versatility makes the XNX transmitter a comprehensive solution for gas detection systems worldwide, catering to diverse industrial needs while ensuring safety and reliability in hazardous environments.

Safety Considerations and Precautions

Always ensure the area is non-hazardous before opening the XNX enclosure under power. Proper grounding of the sensor is essential for intrinsic safety and electrical integrity. Follow all warnings and cautions in the manual to avoid risks and ensure safe operation in hazardous environments.

Warnings and Cautions Before Installation

Always read and understand the manual before proceeding with installation. Never open the XNX enclosure under power unless the area is confirmed to be non-hazardous. Ensure the sensor is properly earthed/grounded for intrinsic safety and electrical integrity. Avoid grounding the sensor through the transmitter to prevent potential risks. Follow all safety guidelines and precautions outlined in the manual to ensure safe and reliable operation. Failure to adhere to these warnings may result in system malfunction or safety hazards. Proper installation practices are critical to maintaining the integrity of the XNX Universal Transmitter in hazardous environments.

Explosion-Proof Standards and Certifications

The Honeywell XNX Universal Transmitter meets rigorous explosion-proof standards, ensuring safe operation in hazardous environments. It is certified for Class 1/Class 2 intrinsic safety and explosion-proof requirements, making it suitable for use in oil, chemical, and industrial applications. The transmitter is globally compliant with explosion-proof regulations, ensuring reliability and safety worldwide. Its robust design and certifications guarantee protection against ignition risks in explosive atmospheres. Additionally, the XNX Universal Transmitter supports hazardous area installations with various mounting options, maintaining explosion-proof integrity. These certifications and standards ensure the device operates safely and efficiently in high-risk environments, adhering to international safety protocols and industry requirements.

Installation Steps and Mounting Options

The XNX Universal Transmitter offers flexible mounting options with five threaded ports in metric or NPT versions, ensuring easy installation in hazardous environments while maintaining durability.

Preparation Steps for Transmitter Installation

Before installing the XNX Universal Transmitter, ensure you have read and understood the Technical Manual 1998M0738. Familiarize yourself with the transmitter’s functions and operation. Prepare the installation site by ensuring proper clearances and environmental conditions. Unpack the transmitter carefully and inspect for any damage. Ground the sensor for intrinsic safety and electrical protection. Gather all necessary tools, mounting hardware, and documentation. Verify compatibility with your chosen sensor type and communication protocols. Ensure the area is safe and non-hazardous before proceeding. Proper preparation ensures a smooth and safe installation process.

Mounting the XNX Universal Transmitter

The XNX Universal Transmitter offers flexible mounting options with five threaded ports available in metric or NPT versions. Ruggedized mounting ensures durability in harsh environments. Ensure proper alignment and secure the transmitter using approved hardware. Verify explosion-proof standards and certifications before installation in hazardous areas. Follow the Technical Manual 1998M0738 for specific mounting dimensions and clearances. Proper grounding and alignment are critical for safe operation and intrinsic safety. Mounting should be done in a way that prevents vibration or stress on the transmitter. Always ensure the area is non-hazardous during mounting to comply with safety protocols. Correct mounting ensures reliable performance and compliance with industry standards.

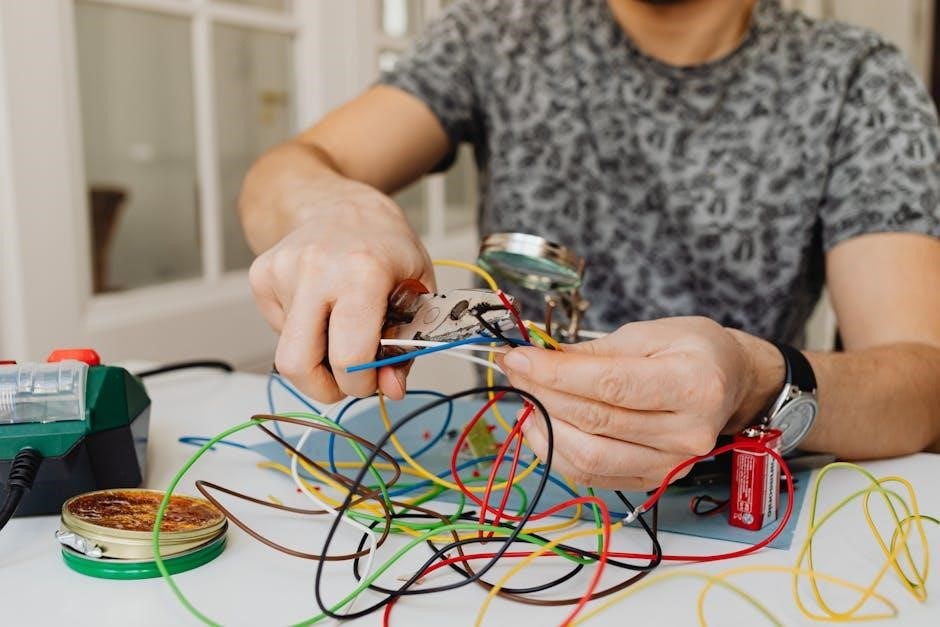

Wiring and Electrical Connections

Proper wiring and electrical connections are critical for the safe and reliable operation of the XNX Universal Transmitter. Always follow the guidelines in the Technical Manual 1998M0738 for wiring instructions. Ensure the sensor is properly earthed or grounded to maintain intrinsic safety. Verify explosion-proof standards and certifications before connecting power. Connect the transmitter to compatible sensors, such as Sensepoint or Searchline Excel, ensuring correct polarity and wiring configuration. Power supply connections must comply with the transmitter’s voltage and current requirements. Use approved cables and connectors to prevent interference and ensure reliable communication. After wiring, perform a thorough check to confirm proper connections and operation before commissioning the system.

Configuration and Setup

The XNX Universal Transmitter requires initial configuration using the HART DTM library for proper operation. Ensure all sensors and inputs are calibrated and integrated for optimal performance.

Initial Configuration of the XNX Transmitter

The initial configuration of the XNX Universal Transmitter involves setting up the device using the HART DTM library. Begin by installing the Honeywell Analytics HART DTM Library, which provides essential tools for commissioning and configuring the transmitter. Once installed, use the HART communicator or a PC-based configuration tool to access the transmitter’s settings. Ensure the device is powered down during the initial setup to avoid any safety risks. Follow the manual’s guidelines to input the correct parameters, such as gas type, range, and alarm levels. Proper configuration ensures accurate gas detection and compliance with safety standards. Always refer to the official manual for detailed instructions to avoid errors.

Calibration and Sensor Integration

Calibration of the XNX Universal Transmitter ensures accurate gas detection and reliable performance. Begin by connecting the transmitter to a HART communicator or PC-based tool for configuration. For sensor integration, select the appropriate sensor type, such as electrochemical, infrared, or millivolt, and follow the manual’s specific instructions. Perform a zero adjustment in a clean air environment and a span adjustment using a known gas concentration. Ensure the sensor is properly grounded to maintain intrinsic safety standards. Refer to the respective sensor manual for detailed integration steps. Regular recalibration is essential to maintain accuracy and compliance with safety standards. Always follow the manufacturer’s guidelines for a safe and precise setup.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance. Clean sensors, inspect wiring, and replace batteries as needed. Use diagnostic tools to identify and resolve issues promptly for reliable operation.

Routine Maintenance Checks

Regular maintenance is essential for ensuring the Honeywell XNX Universal Transmitter operates efficiently and safely. Users should perform routine checks on the sensor, wiring, and electrical connections to prevent malfunctions. The transmitter’s enclosure should be inspected for signs of damage or corrosion, and cleaned periodically to maintain integrity. Additionally, battery levels should be monitored, especially in systems with backup power, to avoid unexpected shutdowns. It is also crucial to verify that all sensors are properly grounded to uphold intrinsic safety standards. By following these steps, operators can guarantee reliable performance and extend the lifespan of the transmitter in hazardous environments.

Troubleshooting Common Issues

Common issues with the Honeywell XNX Universal Transmitter often relate to sensor malfunction, wiring faults, or communication errors. Users should first check sensor connections and ensure proper grounding to maintain intrinsic safety. If the transmitter fails to power on, verify the electrical supply and battery status. For sensor-specific issues, consult the respective sensor manual for troubleshooting steps. Communication errors may require checking the wiring or resetting the transmitter. Regularly reviewing the technical manual and performing routine maintenance can help identify and resolve issues before they escalate. Always ensure the transmitter is properly configured and calibrated to avoid false readings or system downtime in hazardous environments.

The Honeywell XNX Universal Transmitter ensures reliable gas detection, adhering to global explosion-proof standards and offering modular flexibility for hazardous environments, enhancing safety and operational efficiency worldwide.

Final Considerations for Successful Installation and Operation

For optimal performance, ensure all safety guidelines and manual instructions are followed. Verify compatibility with sensors like Sensepoint Optima Plus and Searchline Excel for seamless integration. Proper grounding and wiring are critical for intrinsic safety and explosion-proof functionality. Regular maintenance, including sensor calibration and system checks, is essential to uphold reliability. Familiarize yourself with troubleshooting steps for common issues to minimize downtime. Always refer to the latest manual for updated procedures and certifications. By adhering to these considerations, the XNX Universal Transmitter will provide accurate gas detection, ensuring a safe and efficient operating environment.