The Eurotherm 2116 is a versatile PID temperature controller designed for precise control of industrial processes; Its robust design and advanced features ensure reliable performance in various applications. The Eurotherm 2116 manual provides essential guidance for installation, configuration, and operation, making it a crucial resource for users. Available as a PDF download, the manual offers detailed instructions to optimize the controller’s functionality and troubleshoot common issues. Whether for ovens, chillers, or other thermal systems, the Eurotherm 2116 is a trusted solution for accurate temperature control.

1.1 Overview of the Eurotherm 2116 Series

The Eurotherm 2116 series is a line of advanced PID temperature controllers designed for precise control of industrial heating and cooling processes. These controllers offer universal input options, configurable outputs, and robust alarm systems, making them highly adaptable to various applications. Available in 1/16 and 1/32 DIN sizes, the Eurotherm 2116 series is known for its reliability and ease of use. The Eurotherm 2116 manual provides detailed insights into its features, ensuring optimal performance and troubleshooting. Its flexibility and durability make it a preferred choice for temperature control needs.

1.2 Importance of the Eurotherm 2116 Manual

The Eurotherm 2116 manual is essential for understanding and optimizing the controller’s functionality. It provides detailed installation, configuration, and troubleshooting guidelines, ensuring safe and efficient operation. The manual covers PID control, input/output setups, and alarm systems, helping users maximize the controller’s capabilities. Available as a PDF download, it serves as a comprehensive resource for technicians and operators, enabling them to unlock all features and maintain optimal performance in industrial processes.

Key Features of the Eurotherm 2116 Controller

The Eurotherm 2116 offers advanced PID temperature control, flexible input/output configurations, and robust alarm systems. Its compact design supports precise monitoring and control of industrial processes, ensuring reliability and efficiency in demanding environments.

2.1 PID Temperature Control Capabilities

The Eurotherm 2116 excels in PID temperature control, offering precise and stable regulation of industrial processes. Its advanced algorithms minimize overshoot and optimize responsiveness, ensuring accurate setpoint achievement. The controller supports various thermocouple types and linear 4-20mA inputs, scalable to desired ranges. Detailed tuning options and adaptive control enhance performance, making it ideal for applications requiring stringent temperature management, as outlined in the Eurotherm 2116 manual available for PDF download.

2.2 Input/Output Configurations

The Eurotherm 2116 offers flexible input/output configurations to suit diverse industrial needs. It supports thermocouple and linear 4-20mA inputs, allowing precise measurement and scaling. Two configurable outputs enable control for heating, cooling, and alarms, ensuring versatile process management. The device also features logic I/O options for enhanced functionality. These configurations are detailed in the Eurotherm 2116 manual, available for PDF download, providing clear setup and operation guidance.

2.3 Alarm and Notification Systems

The Eurotherm 2116 features advanced alarm and notification systems to ensure process safety. With up to two alarm outputs, it provides alerts for temperature deviations, process limits, and system faults. Alarms can be configured for high/low limits, deviation, and other critical conditions. The controller also includes visual indicators, such as LED alarms, to notify operators of issues. Detailed setup and configuration instructions for these systems are outlined in the Eurotherm 2116 manual, available for PDF download.

Installation and Configuration

The Eurotherm 2116 requires careful installation, starting with panel cut-out preparation and wiring. Configuration involves setting parameters for optimal performance, as detailed in the Eurotherm 2116 manual PDF.

3;1 Step-by-Step Installation Guide

Begin by preparing the panel cut-out to the specified dimensions for the Eurotherm 2116 model. Mount the controller securely, ensuring proper alignment. Next, connect the wiring according to the Eurotherm 2116 manual PDF, paying attention to input and output terminals. After wiring, power up the device and perform a self-test to verify functionality. Finally, configure the parameters as outlined in the manual for optimal performance. Always refer to the safety guidelines before proceeding.

3.2 Wiring and Electrical Connections

Refer to the Eurotherm 2116 manual PDF for detailed wiring diagrams and electrical connection guidelines. Ensure all terminals are correctly labeled and connected, starting with input terminals for sensors and output relays for heating or cooling devices. Connect the power supply last, following the specified voltage requirements. Double-check all connections to avoid errors. Always disconnect power before servicing to ensure safety. Use appropriately rated wires and follow local electrical standards for a secure installation.

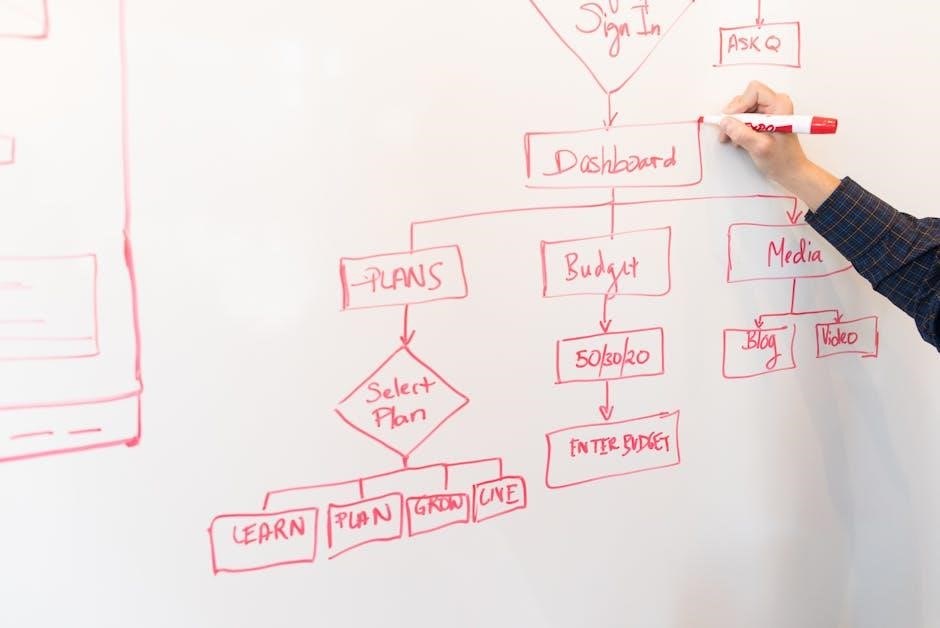

3.3 Configuring Parameters for Optimal Performance

Configure the Eurotherm 2116 by accessing the setup menu via the control panel. Adjust PID settings, input scaling, and output configurations as needed. Set alarm limits and enable advanced features like ramp-soak cycles for precise process control. Refer to the PDF manual for detailed parameter descriptions. After configuration, test the system to ensure accuracy and reliability. Fine-tune settings as required to achieve optimal performance for your specific application.

Operating Instructions

Refer to the PDF manual for step-by-step guidance on startup, operation, and monitoring processes. Use the control panel to navigate menus, adjust settings, and ensure smooth operation.

4.1 Understanding the Control Panel and Indicators

The Eurotherm 2116 control panel features an intuitive interface with a clear LCD display, navigation buttons, and status indicators. The display shows temperature readings, setpoints, and alarm statuses, while LEDs indicate active outputs and alarm conditions. Refer to the PDF manual for detailed descriptions of each button and indicator, ensuring proper interpretation of the controller’s operational status.

Understanding the control panel is essential for configuring and monitoring processes effectively. The manual provides diagrams and explanations to help users navigate the interface and utilize its features efficiently.

4.2 Setting Up and Running the Controller

Setting up the Eurotherm 2116 involves powering on the device, navigating the menu, and configuring parameters such as temperature setpoints and PID values. The PDF manual provides step-by-step instructions for initial setup. Once configured, the controller can be operated in manual or automatic mode. Ensure all outputs are enabled and tested before running the process. The manual also covers advanced features like ramp-soak-dwell and alarm configurations, ensuring smooth operation. Proper setup is crucial for accurate temperature control.

4.3 Advanced Operation Modes

The Eurotherm 2116 offers advanced operation modes for precise temperature control. Features like ramp-soak-dwell profiling and cascade control enable complex process management. Multi-setpoint sequencing and adaptive tuning further enhance performance. These modes are ideal for industrial applications requiring high accuracy. The PDF manual provides detailed instructions for configuring and utilizing these advanced features, ensuring optimal performance and efficiency in temperature regulation. This guide is essential for maximizing the controller’s capabilities in demanding environments.

Specifications and Technical Details

The Eurotherm 2116 controller is available in 1/16 and 1/32 DIN sizes, supporting thermocouple and RTD inputs. It features configurable outputs for heating, cooling, or alarms, ensuring compatibility with various industrial systems. The device operates within specific environmental limits, as detailed in the PDF manual, making it suitable for precise temperature control applications.

5.1 Dimensions and Panel Size Options

The Eurotherm 2116 controller is available in 1/16 and 1/32 DIN panel sizes, ensuring compatibility with standard control panels. Its compact design optimizes space while maintaining functionality. The PDF manual provides precise dimensions for proper installation, ensuring a secure fit in various industrial setups. This flexibility allows the controller to integrate seamlessly into existing systems, making it a versatile choice for temperature control applications.

5.2 Compatibility with Other Systems

The Eurotherm 2116 temperature controller is designed to integrate seamlessly with various industrial systems. Its flexible input/output configurations support compatibility with thermocouples, RTDs, and linear 4-20mA signals. The controller’s modular design allows easy connection to external devices, ensuring efficient communication and control. The PDF manual details compatibility options, enabling users to adapt the controller to their specific process requirements, ensuring optimal performance across diverse applications.

5.3 Environmental and Operational Limits

The Eurotherm 2116 controller operates effectively within specific environmental conditions. It is designed to function in temperatures ranging from 0°C to 55°C and relative humidity up to 80%. The device requires a stable power supply and should be installed in areas protected from extreme vibrations or corrosive substances. For optimal performance, ensure compliance with the specified operational limits outlined in the PDF manual, including proper ventilation and avoidance of direct exposure to harmful substances.

Troubleshooting Common Issues

The Eurotherm 2116 manual provides solutions for common issues like error codes and connectivity problems. It also offers calibration and maintenance tips to ensure optimal performance.

6.1 Identifying and Resolving Error Codes

The Eurotherm 2116 manual provides detailed guidance for identifying and resolving error codes. Users can refer to the manual to understand specific error messages and their causes. Troubleshooting steps include checking wiring, verifying input configurations, and ensuring proper calibration. The manual also offers solutions for common issues like communication faults and sensor malfunctions. Regular maintenance and updates can prevent recurring errors, ensuring smooth operation of the temperature controller. This section is essential for maintaining system reliability and performance.

6.2 Addressing Communication and Connectivity Problems

The Eurotherm 2116 manual offers comprehensive solutions for communication and connectivity issues. It guides users through diagnosing problems such as RS485 serial communication faults and Ethernet connection failures. The manual recommends checking cable integrity, verifying baud rates, and ensuring proper network configurations. Additionally, it provides steps to reset connections and update firmware, ensuring seamless communication between the controller and external devices. These troubleshooting steps help restore connectivity quickly, minimizing downtime and optimizing system efficiency.

6.3 Calibration and Maintenance Tips

The Eurotherm 2116 manual provides detailed calibration and maintenance guidance to ensure optimal performance. Regular sensor calibration is essential for accurate temperature control, and the manual outlines step-by-step procedures. Additionally, it recommends periodic inspection of connections and cleaning of sensors to prevent drift. Users are advised to reset calibration parameters after firmware updates and to follow routine maintenance schedules. Proper adherence to these guidelines ensures precise temperature regulation and extends the lifespan of the controller.

Safety Precautions and Guidelines

Ensure electrical safety by following proper installation and wiring guidelines. Handle the controller with care to avoid damage. Store the device in a dry, cool environment. Refer to the Eurotherm 2116 manual for detailed safety protocols to prevent hazards and maintain optimal performance.

7.1 Electrical Safety Measures

Always follow proper electrical safety protocols when handling the Eurotherm 2116 controller. Ensure all connections are made by qualified personnel to avoid risks of electrical shock or damage. Use appropriate insulation and grounding to prevent overvoltages. Disconnect power before performing any maintenance or repairs. Refer to the Eurotherm 2116 manual for specific guidelines on electrical safety to ensure safe and reliable operation of the device.

7.2 Handling and Storage Recommendations

Handle the Eurotherm 2116 with care to prevent damage. Store it in a dry, clean environment away from direct sunlight and extreme temperatures. Avoid exposing the controller to moisture or corrosive substances. When shipping, use original packaging or equivalent materials to protect against shock and vibration. For detailed handling and storage guidelines, consult the Eurotherm 2116 manual to ensure optimal preservation and functionality of the device.

Eurotherm 2116 Manual PDF Download Options

The Eurotherm 2116 manual is available for download from official Eurotherm websites and trusted third-party sources. Ensure authenticity by verifying the publisher and format before downloading the PDF to access essential operation and installation guides.

8.1 Official Eurotherm Downloads and Resources

The official Eurotherm website provides direct access to the Eurotherm 2116 manual in PDF format. Users can visit the Eurotherm Downloads section to find the latest version of the manual, ensuring authenticity and reliability. Additional resources, such as user guides and installation handbooks, are also available; The official site offers a secure and trusted source for downloading essential documentation, eliminating risks associated with third-party sources. Use the search function to quickly locate the Eurotherm 2116 manual and access comprehensive operating instructions.

8.2 Third-Party Sources for Manual Access

In addition to official sources, third-party websites like ManualsLib and ManualsOnline offer free access to the Eurotherm 2116 manual. These platforms provide convenient PDF downloads, often indexed for easy searching. While these sources are helpful, users should verify the authenticity and completeness of the documents. Some third-party sites may include ads or require registration, but they remain a viable option for obtaining the manual when official resources are inaccessible. Always ensure the source is reliable to avoid downloading incomplete or incorrect versions.

Discontinuation of the Eurotherm 2116 Series

The Eurotherm 2116 series was discontinued in November 2014; While the manual remains available for download, users are advised to consider newer models for updated features and support.

9.1 End-of-Life Announcement and Implications

The Eurotherm 2116 series was officially discontinued in November 2014, as announced by the manufacturer. This end-of-life declaration means that production, direct sales, and official support for the model have ceased. While the Eurotherm 2116 manual PDF remains available for download, users are encouraged to migrate to newer, supported models for enhanced functionality and security. The discontinuation underscores the importance of upgrading to maintain optimal performance and compliance with current standards.

9.2 Recommended Alternatives and Upgrades

Users of the discontinued Eurotherm 2116 are advised to consider upgrading to the Eurotherm 2132 or 2200 series controllers, which offer enhanced functionality and compatibility. These newer models provide advanced PID control, digital communication options, and improved user interfaces. Additionally, the 2400 series offers touchscreen operation and Industry 4.0 readiness, ensuring compliance with modern industrial standards. Upgrading ensures continued support, improved performance, and access to the latest features for precise temperature control applications.